The Automotive Die Casting Lubricant Market is gaining significant traction owing to its essential role in the metal casting industry, particularly in the production of lightweight, durable components for vehicles. As automotive manufacturers shift focus towards fuel efficiency, emission reduction, and performance optimization, die casting processes and their associated lubricants have become critical to manufacturing efficiency and product quality.

Die casting is a metal casting process that forces molten metal into a mold cavity under high pressure. In the automotive industry, this technique is predominantly used to create complex, high-strength, and lightweight components such as engine blocks, transmission cases, and structural elements. Die casting lubricants are vital to this process. They are applied to molds to prevent metal adhesion, reduce friction, facilitate component ejection, and enhance mold longevity. These lubricants ensure optimal surface finish, dimensional accuracy, and overall productivity.

The market for automotive die casting lubricants is projected to grow robustly over the coming years, driven by increasing automotive production, the growing trend of vehicle lightweighting, and advancements in lubrication technology.

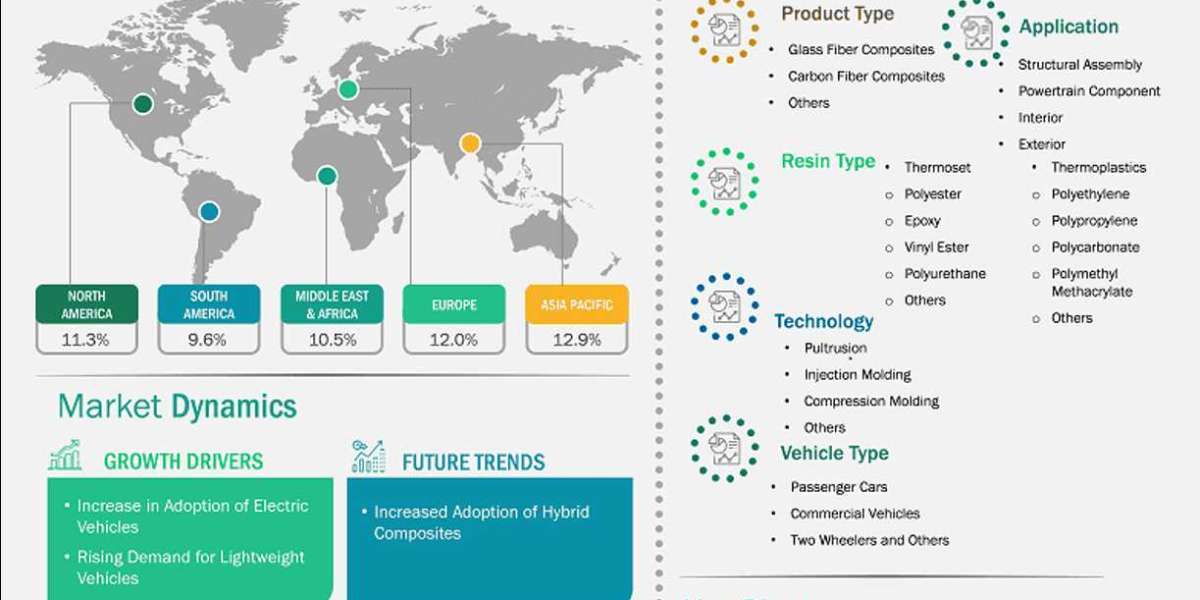

Automotive Die Casting Lubricant Market CAGR (growth rate) is expected to be around 4.00% during the forecast period (2025 - 2034).

Drivers

- Rising Automotive Production: The global demand for passenger and commercial vehicles continues to rise, particularly in emerging economies like China, India, Brazil, and Southeast Asian nations. This growth boosts the requirement for high-performance die-cast parts, thereby fueling demand for die casting lubricants.

- Lightweighting Initiatives: The automotive industry is prioritizing weight reduction to improve fuel efficiency and reduce carbon emissions. Lightweight materials such as aluminum and magnesium alloys are increasingly used in die casting. Specialized lubricants are essential to cast these metals effectively, creating significant growth opportunities.

- Shift Toward Electric Vehicles (EVs): Electric vehicle manufacturing involves high-precision components like battery housings, motor casings, and powertrain structures, many of which are produced using die casting. The surge in EV production is expected to amplify the need for die casting lubricants tailored for these advanced applications.

- Technological Advancements: Innovations in lubricant formulations, such as water-based, semi-synthetic, and synthetic lubricants with low environmental impact, higher efficiency, and better thermal stability, are expanding the market landscape. These lubricants also comply with increasingly stringent environmental and workplace safety regulations.

Key players in the Automotive Die Casting Lubricant Market include:

MOL Group, Castrol, Valvoline, Cargill, Chevron, TotalEnergies, Lukoil, Fuchs Petrolub SE, BP, Performance Lubricants, Factorial Energy, Shell, PetroCanada, High Performance Lubricants, ExxonMobil.

Challenges

- Volatility in Raw Material Prices: Die casting lubricants are composed of various raw materials, including base oils and additives. Fluctuating prices of petroleum-derived products can impact production costs and profit margins.

- Environmental Regulations: Traditional die casting lubricants, especially solvent-based ones, can emit volatile organic compounds (VOCs) and pose environmental and health hazards. Regulatory pressures are compelling manufacturers to shift toward greener alternatives, which can involve high RD investments and market adaptation challenges.

- Competition from Alternative Manufacturing Techniques: Advancements in additive manufacturing and alternative casting methods may offer substitutes for traditional die casting processes in certain applications, potentially impacting lubricant demand.

For More Information Request for Sample PDF

Emerging Trends

- Eco-Friendly Formulations: The development of biodegradable and non-toxic lubricants is a major trend, aligning with global sustainability goals and regulatory compliance.

- Smart Lubrication Systems: Integration of IoT and automation in die casting processes enables real-time monitoring and precise application of lubricants, reducing waste and improving efficiency.

- Customization for EV Components: Tailored lubricants that enhance thermal management and corrosion resistance in electric vehicle components are gaining traction.

- Recycling and Waste Minimization: Lubricant recyclability and systems for minimal residue are being developed to reduce environmental impact and improve cost efficiency.

Contact Us:

Market Researcnh Future (Part of WantStats Research and Media Pvt. Ltd.)

Contact Number. +91 2269738890

Email: sales@marketresearchfuture.com